Murray Mold & Die

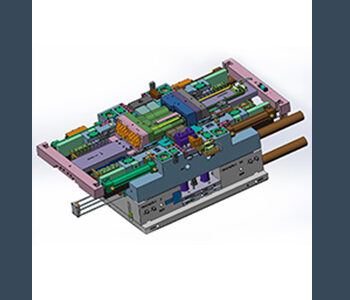

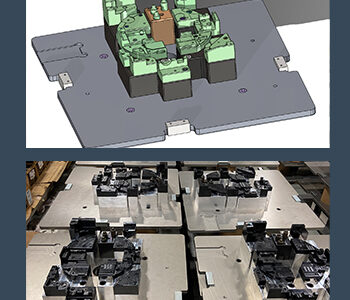

MM&D specializes in Injection Molds and Design but is fully capable of designing and manufacturing Casting Dies and Trim Tools, Extrusion Dies, Assembly Machines, Stamping Dies, and Precision Replacement Tooling. Our team can custom design the mold for you from concept with our modeling capability, or even help you with rebuilding and repairing a die that has been in production for years. We are setup with several companies on rotating preventative maintenance and would love to add yours to it.

Work with us

Providing precision and quality machining since 1985

Testimonials

I have been working with MMD for several years, and not once can I recall a lack in professionalism. They always aim to deliver parts for the most cost effective and fastest way possible, always meeting the agreed upon deadline. Murray Mold & Die also has the most competitive prices, while still maintaining reasonable lead times. They never fail to impress me.

I would highly recommend Murray Mold and Die to anyone who needed quality machining work done by professionals who know what they are doing. We have been doing business with MMD since moving here from Pennsylvania and they have consistently met and exceeded our expecations. Injection molds are extremely difficult to evaluate and repair. Because of their expertise, they can affect the repair in a relatively short period of time, especially compared to other shops we have done business with.

I’ve used Murray Mold and Die for the last 10 years and I have always received quality work. Their very fair on pricing, quick turnaround time and great customer service. Jerry and his team always pay close attention to detail and quality that’s evident in every party. I would highly recommend MMD to anyone no matter what size the job